DMS CNC 5-axis Heavy Duty Router Model 5U6-12-6-60S, New 2020, 6' x 12' table, 60" vertical Z axis,

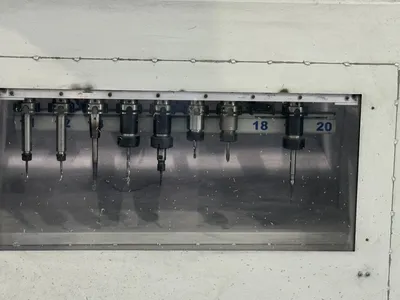

27 HP HSK63 spindle, 20 position tool changer, Fagor CNC Controls

MANUFACTURER MACHINE

MODEL NUMBER

MACHINE CONSTRUCTION

TABLE SIZE

Diversified Machine Systems Inc. (OMS)

This 5-Axis U-Frame overhead gantry machine features a fixed table with a fixed-top enclosure, and also includes manual front doors with safety interlocks, and a solid back wall. This machine is capable of Maximum Rapid Feedrates of 1600 inches per minute.

5U6-12-6-60S-xxxxx

OMS machines are constructed of a rigid, fabricated steel base. utilizing heavy gauge steel tube and plate weldment construction throughout. All structural members are stress relieved for maximum stability, and all surfaces that mount precision components are precision ground and/or machined. 6061 T6 aluminum plate is used on the table surface and some Z-axis components. All linear axes are laser aligned and compensated for positional accuracy.

This machine features an 144" x 72" aluminum table top, machined flat, with 3/8"-16 threaded inserts on 12" centers. This table will be mounted to the machine's low profile frame. and the table top will be approximately 19" to the floor.

The X-axis is the axis that travels across the bridge.

The Heavy-Duty Bridge will span the 144" dimension of the table. Approximate travel of X-axis is 156 inches.

Maximum Feed rate is 1200 inches per minute.

The Bridge Rails and Bearings will be 45 mm Roller Bearings.

The X-axis is driven by a spinning recirculating ball nut, lead screw assembly. The lead screw does not spin and the ends are fixed for higher preload.

The Y-axis is the Overhead Gantry Axis.

The Gantry will travel the 72-lnch dimension of the table. Approximate travel Y-axis is 84 inches.

Maximum Feed rate is 1200 inches per minute.

The Gantry Rails and Bearings will be 45 mm Roller Bearings.

The Gantry is driven by a pair of spinning recirculating ball nut, lead screw assembly (one on each side of the Gantry). The lead screw does not spin and the ends are fixed for higher preload.

CONTROLLER

The Z-axis travel is 60 inches.

Maximum Feed rate 1000 inches per minute. The Rails are 45 mm Roller Bearings.

The Z-axis is driven by a recirculating ball nut, lead screw assembly. The lead screw spins and is supported on each end by angular contact bearings.

The C-axis rotates parallel to the table. The C-axis travel is+/- 320 degrees.

Maximum Rotational speed is 12500 degrees per minute.

The B-axis rotates perpendicular to the table. The B-axis travel is +/- 120 degrees.

Maximum Rotational speed is 10000 degrees per minute.

This Machine features a Hiteco Bi-Rotary Tilt V Series 90 Head, which includes a

26.8HP (20KW) liquid-cooled, Quick-Change Spindle with through-the-tool air blast. A frequency inverter with electronic braking is used to program the spindle speed from 500 to 24,000 rpm. The tool holders used on this spindle are HSK63A. This head assembly also will include Pnuematic Brakes for both Band C axes, as well as Heidenhain rotary scales.

The Model 8065 Controller. This controller is fully compatible with all popular CAD/CAM software 5-Axis post processor files. Some of the many features include: a 1O" Color LCD Screen, 32GB Memory, the MP-Plus option for high-speed machining (doubles the standard block processing speed), 3D Graphics, communications software, DNC communications via a TCPIP connection, and Tool Center Point Compensation. The main electric cabinet is mounted on the machine structure and includes an industrial A/C unit for proper cooling.

Number of Axis: 5-Axis U-Frame Overhead Grantry Machine w/ Fixed Table

Tool Changer: (20) Position Auto Tool Changer

Table Size: 144" x 72" Aluminum Table Top (3/8" - 16 Threaded Inserts on 12" Centers)

High Perf Tool Height Sensor: Renishaw Tool Height Sensor

Spindle Mfg: Hiteco Bi-Rotary Tilt V Series 90 Head (HSK63A)

Control: Fagor 8065

Spindle Speed: 24,000 RPM

Power Requirement: 440v/3ph/60hz (80 Amps)

Spindle Motor: 26.8HP (20 kW)

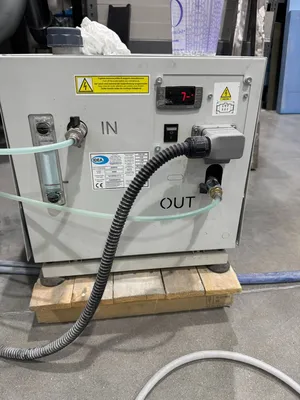

Air Requirements: 5 CFM at 100 PSI / The ATC Spindle Requires Min. of 100 PSI for Tool Release

Z-Axis Travel: 60"

Pneumatic Brakes: For Both B & C Axes / As well as Heidenhain Rotary Scales

EQUIPPED WITH :

Fagor Sercos Digital Drives &

Roller Rails

Fagor AC Brushless Servo Motors on All Axis

Safety Light Tower

Hand-Held Programmer (Teach Pendant)

Top Enclosure

Renishaw RMP 600 Radio Machine Probe

Auto Lube

Only 5000 spindle hours

We use cookies to improve your experience. Privacy Policy.