For sale: Hardinge T-42 MSY Big Bore Super Precision CNC Lathe. Features include live tooling, Y-axis, sub-spindle, and BMT 45 turret. Equipped with high-pressure coolant, custom chip control, and precision tooling. Lightly used.

• Live Tooling Sub-Spindle, Y-Axis, Glass Scales

• 2” Main Spindle Capacity

• 1.625” Sub Spindle Capacity

• 16 Station Bi-Directional BMT 45 Turret with 1/2 Station Index

• Repeatability: 30 millionths (0.00003”)

• 1000 PSI High Pressure Coolant

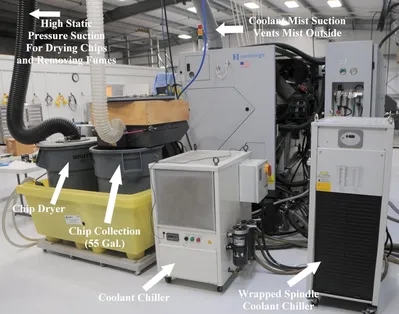

• Custom High Pressure Adjustable Flow Pneu-matic Chip Control System

• Capable of Hard Turning

• LNS Quick Load Servo 80 S2 Bar Feeder Ex-tended In-feed Table; 12 Spindle Liners

• LNS Turbo MH-250 Variable Speed Chip Conveyor with 250 micron Filtration

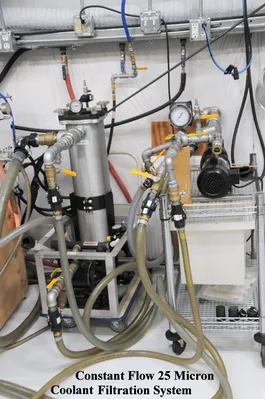

• Custom Continuous 25 micron Coolant Filtra-tion System 12 gpm (no chips enter the cool-ant) coupled with Custom LNS Coolant Tank

• Ventilation System sends Coolant Mist outside

• Auxiliary High Flow Coolant System

• Heated Coolant Cleaning System (Makes Cleaning Inside The Lathe Easier)

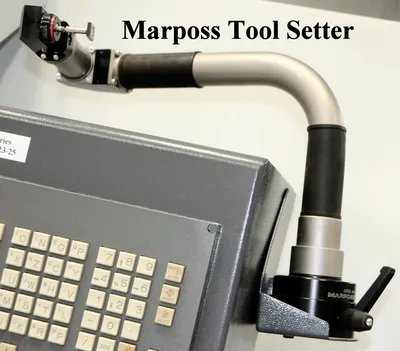

• Marposs PrecisionTool Setter

• Custom Chip Catcher/Coolant Recycler/Chip Dryer System (Returns Chip Conveyor Drag-in Coolant to Coolant Tank and dries chips for easy handling)

• Approximately $10,000 of Tooling (BMT Hold-ers, Spindle Tooling, Misc. Tooling

• Fanuc Series 31i-Model A

• New Replacement cost ~$700,000

• One owner/operator, always operated in our Fully Climate Controlled Shop

• Cutting Time: 7842 hours (equivalent to 2 years of 2 shift operation)

• Light Turning only, no Heavy or Hard Turn-ing ever on this Lathe

• Materials cut: Delrin, Polycarbonate, 15/64” diameter annealed tool steel, 1/2” St. St.

• Excellent Condition, Meticulously Maintained

• Reliable Unattended “Lights Out– Over-Night” Operation

We use cookies to improve your experience. Privacy Policy.