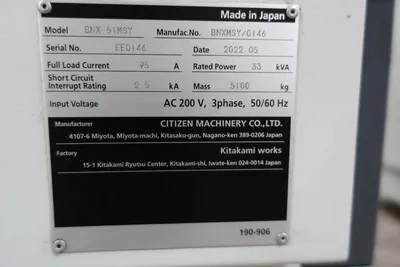

MIYANO BNX-51MSY Multi-Axis CNC Lathe, 2022 demo unit, offers advanced machining capabilities with dual spindles, 12-station turret, and Mitsubishi M70V control. Max work size: 2" diameter bar, 5.9" length.

BNX-51MSY

Machining Capacity: Maximum machining length 150 mm

Machining Capacity: Diameter of standard cutting (Spindle No. 1) 51 mm Dia.

Machining Capacity: Diameter of standard cutting (Spindle No. 2) 51 mm Dia.

Chuck size: Spindle No. 1 6 inch

Chuck size: Spindle No. 1 5 inch

Spindle: Number of spindle 2

Spindle: Spindle speed range (Spindle No. 1) 5,000 min-1

Spindle: Spindle speed range (Spindle No. 2) 5,000 min-1

Spindle: Inner diameter of draw tube (Spindle No. 1) 52 mm Dia.

Spindle: Inner diameter of draw tube (Spindle No. 2) 43 mm Dia.

Spindle: Collet chuck (Spindle No. 1) H-S22, (DIN177E - option)

Spindle: Collet chuck (Spindle No. 2) H-S22, (DIN177E - option)

Spindle: Power chuck (Spindle No. 1) 6" thru-hole chuck

Spindle: Power chuck (Spindle No. 2) 5" thru-hole chuck

Turret: Number of turret 1

Turret: Type of turret (Turret No. 1) 12 station turret

Turret: Shank height of square turning tool 3/4" Sq.

Turret: Diameter of drill shank 1" Dia.

Revolving tools: Number of revolving tool (Turret No. 1) Max. 12

Revolving tools: Type of revolving tool (Turret No. 1) Single clutch

Revolving tools: Tool spindle speed range (Turret No. 1) 6,000 min-1

Revolving tools: Machining capacity Drill (Turret No. 1) Max. 13 mm Dia.

Revolving tools: Machining capacity Tap (Turret No. 1) Max. M12×1.75 (S45C-D)

Slide stroke: Turret slide stroke (X1 axis) 165 mm

Slide stroke: Turret slide stroke (Z1 axis) 300 mm

Slide stroke: Turret slide stroke (Y1 axis) 80 (±40) mm

Slide stroke: Spindle slide stroke (X2 axis) 86 mm

Slide stroke: Spindle slide stroke (Z2 axis) 553 mm

Feed rate: Rapid feed rate (X1) 20 m/ min

Feed rate: Rapid feed rate (Z1) 20 m/ min

Feed rate: Rapid feed rate (Y1) 12 m/ min

Feed rate: Rapid feed rate (X2) 20 m/ min

Feed rate: Rapid feed rate (Z2) 20 m/ min

Motors: Spindle drive (Spindle No. 1 Cs) 15/ 11 kw (15 min/ cont.)

Motors: Spindle drive (Spindle No. 2 Cs) 7.5/ 5.5 kw (15 min/ cont.)

Motors: Revolving tool drive (Turret No. 1) 4.0 kw

Motors: Slide 1.5 kw (Z1), 1.2 kw (X1, Y, X2, Z2)

Motors: Hydraulic oil motor 1.36 kw

Motors: Lubricating oil motor 0.004 kw

Motors: Coolant pump 0.25 kw×1, 0.18 kw×1

Motors: Turret index motor 1.0 kw

Power supply: Voltage AC 200/ 220±10% 50/ 60 Hz±1%

Power supply: Capacity 33 KVA

Power supply: Air supply 0.5 MPa

Power supply: Fuse 100 A

Tank capacity: Hydraulic oil tank capacity 2.6 gal

Tank capacity: Lubricating oil tank capacity 1 gal

Tank capacity: Coolant tank capacity 79 gal

Machine height 1,700 mm

Floor space 3,907 × 1,540 mm (w/chip conveyor)

Machine weight 11,240 lb

Miyano BNX-51MSY

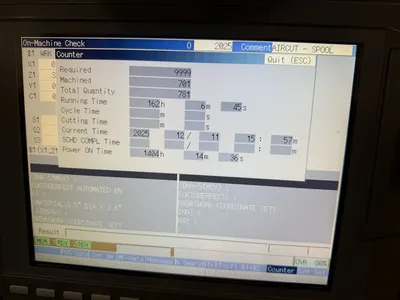

The BNX-51MSY includes the new, more powerful Mitsubishi M70V control that comes standard with a multitude of user-friendly CNC attributes. Featuring superimposition control where machining is performed with the movement of the back spindle synchronized with that of the tool slide.

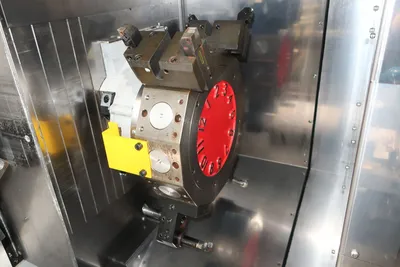

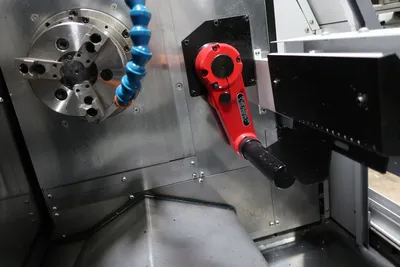

The 12-station turret, allowing revolving tools to be mounted at all stations, incorporates a Y-axis and supports the machining of complex shapes. Longer and larger workpieces can be handled thanks to the extended stroke of the X1 axis, increased capacity of the servomotor, extended stroke of the X2 axis and increased back spindle chuck size.

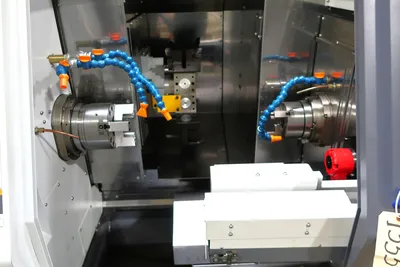

This two spindle, one turret machine featuring simultaneous control supports the machining of complex and precision parts.

Fixed headstock type CNC Automatic Lathe

7-cutting axes (X1, Z1, Y1, X2, Z2, C1, C2)

Two spindles

One turret

One Y-axis slide

25-Nm twelve revolving tool stations

2" diameter bar capacity

5.9" work length

Functions

Standard NC functions

• Spindle C axis control (main-back)

Spindle synchronization function (main - back)

User macros

Canned cycle for drilling

Constant surface speed control

Polygon turning

Spindle synchronized tapping function (main-back)

Tool spindle synchronized tapping function

• Sub-inch control

Milling interpolation

Helical interpolation

Multiple repetitive cycle for turning I/II

B code I/F

Tool diameter offset

Nose radius compensation

High speed program check

• Optional block skip (1 set)

Superimposition of control axes

Torque skip function

Corner chamfering/Corner rounding

Arbitrary axis exchange function

Continuous thread cutting

Network I/O function

________________________________________

Functions

Other functions

• Variable lead thread cutting function

High speed synchronized tapping function

Simultaneous thread cutting in two axis control groups 1

• Simultaneous thread cutting in two axis control groups 2

Tool life management I

External memory running

• Program storage capacity 320m, 600m

Common variables (50 + 50 * Number of axis control groups)

Common variables (100 + 100 * Number of axis control groups)

Accessories

Standard Accessories

• SP1/SP2 Chucking Device H-S22

Splash guard interlock

Spindle Air Blow

Spindle Brake

SP2 Work Ejector & Inner High Pressure Coolant

• Part Conveyor

3-Color Signal Tower

Total & Preset Counter (Custom Menu)

Cut-Off Confirmation (Electric Type)

• Barfeeder Interface

Coolant Level Switch

Optional Accessories

• Parts Carrier

• 3-Jaws Chuck Systems

NEW PRICE TODAY $290,000

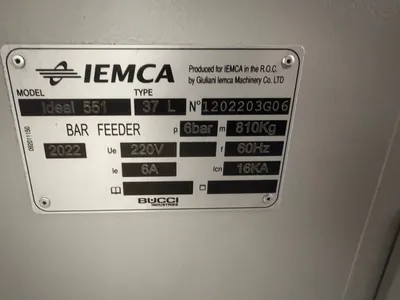

IEMCA IDEAL 551 BARFEEDER

We use cookies to improve your experience. Privacy Policy.